The Function of Fasteners and Machining in High-Quality Item Style

The Function of Fasteners and Machining in High-Quality Item Style

Blog Article

Browsing the Globe of Fasteners and Machining: Approaches for Accuracy and Speed

In the detailed realm of bolts and machining, the pursuit for precision and rate is a perpetual obstacle that demands thorough interest to detail and calculated planning. From recognizing the diverse selection of bolt types to selecting optimal materials that can endure strenuous needs, each action in the procedure plays an essential role in achieving the preferred end result. Accuracy machining techniques better raise the intricacy of this craft, requiring a delicate equilibrium in between technical experience and innovative approaches. As we look into the techniques that can boost both rate and efficiency in this domain name, the interplay between quality assurance steps and operational excellence becomes a vital focal factor.

Understanding Fastener Types

When selecting fasteners for a task, understanding the different types available is vital for guaranteeing optimal performance and dependability. Bolts can be found in a variety of kinds, each created for specific applications and requirements. Bolts are utilized with nuts to hold products with each other, while screws are functional bolts that can be utilized with or without a nut, relying on the application. Nuts, on the various other hand, are internally threaded fasteners that mate with screws or bolts, offering a protected hold. Washing machines are crucial for distributing the tons of the bolt and avoiding damages to the material being fastened. In addition, rivets are permanent fasteners that are ideal for applications where disassembly is not needed. Understanding the distinctions between these bolt kinds is necessary for choosing the right one for the work, ensuring that the link is solid, durable, and reputable. By choosing the proper bolt kind, you can optimize the performance and long life of your job - Fasteners and Machining.

Picking the Right Products

Recognizing the relevance of picking the right materials is vital in ensuring the ideal performance and dependability of the selected bolt kinds talked about formerly. When it concerns fasteners and machining applications, the material choice plays a crucial duty in figuring out the general strength, sturdiness, rust resistance, and compatibility with the intended environment. Different products provide differing buildings that can substantially affect the efficiency of the bolts.

Usual products used for fasteners consist of steel, stainless steel, brass, aluminum, and titanium, each having its special strengths and weaknesses. Steel is renowned for its high stamina and durability, making it appropriate for a wide array of applications. Picking the appropriate product includes taking into consideration aspects such as toughness requirements, ecological conditions, and budget plan constraints to make sure the preferred performance and durability of the fasteners.

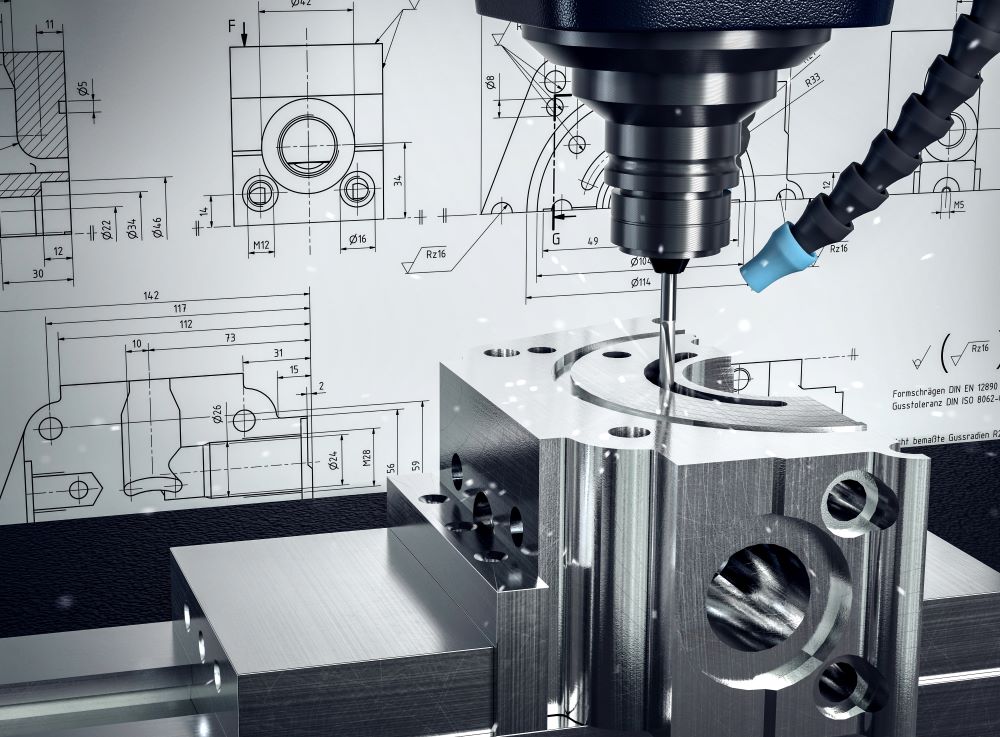

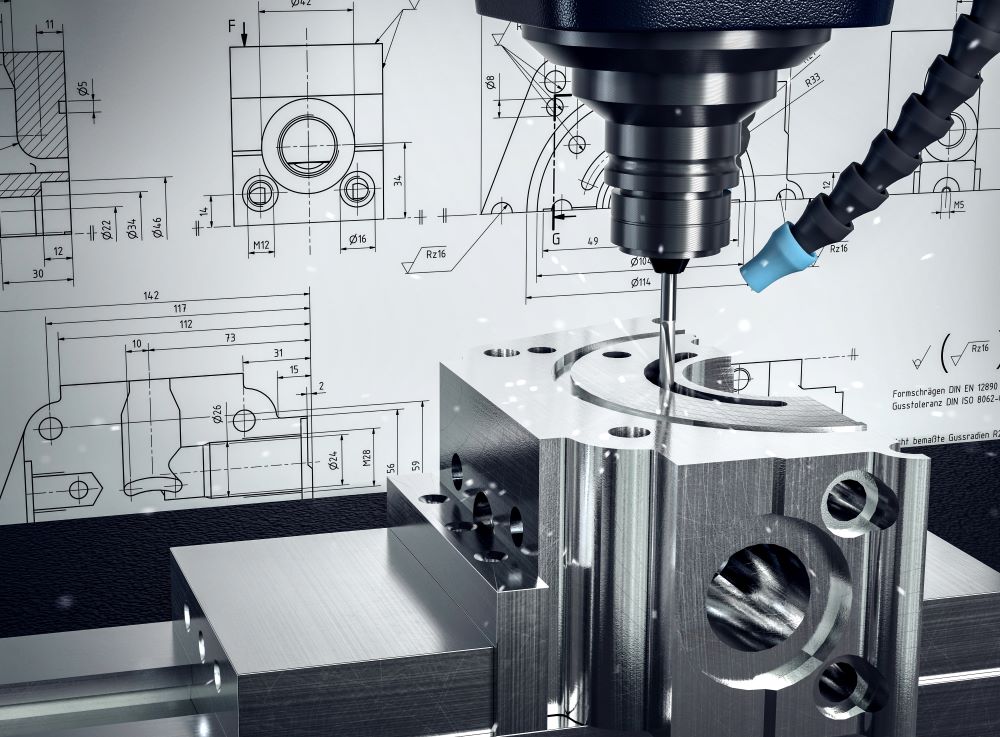

Precision Machining Techniques

Along with CNC machining, other precision techniques like grinding, transforming, milling, and boring play vital duties in bolt manufacturing. Grinding aids accomplish great surface finishes and limited dimensional tolerances, while turning is often utilized to create cylindrical elements with specific diameters. Milling and exploration procedures are essential for shaping and producing holes in bolts, guaranteeing they fulfill specific requirements and feature appropriately.

Enhancing Speed and Efficiency

To optimize bolt production processes, it is vital to streamline operations and implement effective strategies that complement precision machining strategies. One crucial method for improving speed and efficiency is the application of lean manufacturing concepts. By lowering waste and concentrating on constant enhancement, lean techniques assist optimize and eliminate bottlenecks operations. Furthermore, purchasing automation innovations can dramatically boost production speed. Automated systems can handle recurring tasks with precision and speed, permitting workers to concentrate on even more complicated and value-added tasks. Taking On Just-In-Time (JIT) inventory monitoring can additionally boost efficiency by ensuring that the appropriate materials are offered at the ideal time, reducing excess inventory and reducing preparations. Moreover, cultivating a culture of partnership and interaction amongst group participants can boost overall efficiency by promoting transparency, problem-solving, and technology. By integrating these techniques, manufacturers can attain an equilibrium in between rate and precision, eventually improving their one-upmanship in the bolt industry.

Top Quality Control Steps

Applying strenuous high quality control you can try here steps is essential in ensuring the integrity and consistency of fastener items in the manufacturing procedure. Fasteners and Machining. Quality control procedures encompass numerous stages, starting from the choice of raw materials to the last evaluation of the finished bolts. This involves analyzing aspects such as material stamina, make-up, and toughness to ensure that the bolts fulfill market criteria.

Normal calibration of equipment and equipment is vital to maintain consistency in manufacturing and guarantee that bolts meet the needed tolerances. Carrying out strict procedures for recognizing and addressing flaws or non-conformities is important in protecting against substandard products from entering the marketplace. By establishing a detailed top quality control structure, producers can maintain the online reputation of their brand and deliver fasteners that satisfy the greatest criteria of efficiency and durability.

Conclusion

In the elaborate world of fasteners and machining, the quest for accuracy and rate is a perpetual challenge that demands meticulous focus to information and strategic preparation. When it comes to bolts and machining applications, the product choice plays a critical duty in determining the total toughness, longevity, deterioration resistance, and compatibility with the desired atmosphere. Precision machining involves different advanced techniques that guarantee the tight tolerances and requirements needed for fasteners.In addition to CNC machining, various other accuracy methods like grinding, turning, milling, and exploration play crucial functions in fastener manufacturing.To enhance fastener manufacturing procedures, it is vital to improve procedures and carry out effective strategies that enhance precision machining techniques.

Report this page